Precision aluminum casting and Aluminum Foundry partnerships that drive industrial success

Wiki Article

Exactly How Factory Provider Enhance Manufacturing Efficiency and High Quality in Industrial Applications

Shop solutions play an important function in boosting manufacturing performance and quality across various industrial applications. By executing sophisticated steel spreading strategies, these solutions assure parts are made with accuracy and uniformity. This not just lowers preparations yet additionally minimizes waste, fostering better collaboration between factories and makers. The effect of high-grade parts on functional performance raises essential questions about the future of commercial manufacturing. What technologies exist ahead in this developing landscape?The Role of Shop Solutions in Streamlining Manufacturing Processes

Furthermore, factories often supply competence in alloy growth, enabling producers to make use of advanced materials that enhance item efficiency. The cooperation in between foundries and manufacturers cultivates a far better understanding of manufacturing demands, leading to optimized procedures and improved item designs. By leveraging factory services, makers can accomplish higher adaptability, adjust to altering market demands, and preserve competitiveness in the industry. Overall, the role of foundry solutions is essential in helping with a much more cost-effective and efficient manufacturing landscape.

Advanced Technologies in Foundry Procedures

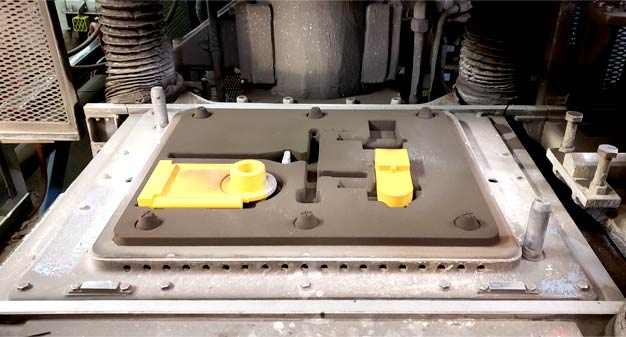

Cutting-edge modern technologies are changing factory operations, significantly improving productivity and precision. Automation plays an essential role, with robot systems enhancing repeated tasks such as molding and product handling. Furthermore, advancements in computer-aided style (CAD) and computer-aided manufacturing (CAMERA) systems allow shops to produce complex geometries with better precision and reduced product waste.Additionally, the integration of expert system (AI) and device understanding improves quality assurance by keeping track of procedures in real-time and forecasting potential defects prior to they happen. The usage of sophisticated products, such as lightweight alloys and compounds, further enhances the efficiency characteristics of actors items.

Furthermore, 3D printing modern technology is transforming prototyping and tooling, permitting for quick customization and minimized preparations. Jointly, these innovative technologies not only raise production effectiveness yet also guarantee that the end products meet strict high quality criteria, placing shops at the forefront of modern industrial applications.

Reducing Lead Times Through Efficient Factory Practices

Effective foundry methods play an essential duty in reducing lead times within manufacturing settings. By implementing streamlined manufacturing processes and progressed organizing techniques, producers can improve process and enhance source appropriation. These improvements not only accelerate output but also contribute to overall functional performance.Structured Manufacturing Processes

Improving production procedures is crucial for reducing preparations in the production industry. Efficient foundry techniques, consisting of enhanced workflows and source administration, play an important function in achieving this objective. By lessening waste and enhancing interaction among groups, factories can considerably improve their functional effectiveness. The implementation of standard procedures additionally adds to consistent top quality and faster turn-around times, allowing manufacturers to react more promptly to market demands. In addition, the combination of advanced modern technologies, such as automation and real-time tracking systems, aids in determining traffic jams and assisting in timely treatments. Generally, a concentrate on structured manufacturing processes not just increases preparations however likewise improves the general competition of industrial applications, guaranteeing that products satisfy customer expectations properly.Advanced Scheduling Techniques

Efficient manufacturing processes naturally lead suppliers to explore innovative scheduling techniques as a way to further minimize preparations. By employing advanced formulas and software, foundries can enhance operations, aligning production timetables with need forecasts and resource accessibility. Strategies such as Just-In-Time (JIT) organizing minimize inventory expenses while making sure prompt product delivery, thus improving functional performance. In addition, incorporating real-time information analytics allows foundries to expect prospective delays and change routines proactively. This flexibility not just simplifies procedures but also boosts overall productivity. Additionally, collective planning with consumers and distributors can foster a more synchronized supply chain, more reducing preparations. Eventually, these sophisticated scheduling techniques encourage shops to accomplish higher efficiency and premium top quality in their manufacturing processes.Ensuring Accuracy and High Quality in Metal Spreading

Guaranteeing accuracy and high quality in metal spreading needs a precise approach that incorporates every stage of the production procedure. This process begins with mindful style and design of the mold and mildews, guaranteeing they can hold up against the molten steel's temperature level and stress. The choice of premium raw materials is essential, as pollutants can compromise the last product.As soon as the materials are prepared, specific temperature control throughout melting and pouring is basic to accomplish the preferred residential properties in the actors metal. Keeping an eye on solidification and cooling rates more assurances dimensional precision and surface coating.

Quality assurance techniques, such as non-destructive testing and examination, are vital to identifying flaws early at the same time. Aluminum Casting Company. Additionally, utilizing experienced workers that understand the subtleties of steel casting contributes substantially to maintaining high requirements. On the whole, these practices collectively improve the integrity and efficiency of cast elements in numerous commercial applications

Minimizing Waste and Maximizing Resource Application

Additionally, reusing scrap metal within the shop itself can considerably decrease waste, changing byproducts into usable resources. Lean making principles also add to throw away decrease by improving processes and removing unnecessary steps, bring about a lot more effective operations.

In addition, routine maintenance aluminum casting of tools assurances peak performance, protecting against malfunctions that can lead to thrown away materials. By concentrating on these strategies, shops not only lower expenses yet likewise add to sustainable techniques, aligning with the expanding demand for ecologically responsible manufacturing approaches in commercial applications.

The Affordable Advantage of High-Quality Elements out there

Top notch components supply a significant affordable benefit in the foundry market, where accuracy and resilience are extremely important. Producers that focus on premium materials and workmanship can boost product performance and integrity, leading to boosted consumer satisfaction. This advantage is especially obvious in sectors such as automotive and aerospace, where component failure can have disastrous effects.Moreover, top notch parts frequently lead to reduced upkeep prices and extended product life expectancies, which can be attractive marketing factors for possible customers. As market demands expand for sustainable and efficient technologies, the focus on quality becomes even more crucial. Business that invest in top notch shop solutions not only enhance their production processes but additionally separate themselves from rivals who may sacrifice top quality for price financial savings. Subsequently, the commitment to premium components ultimately converts right into a stronger market position and lasting service success.

Frequently Asked Inquiries

What Types of Materials Do Shop Solutions Usually Collaborate With?

Shop solutions usually deal with steels such as light weight aluminum, brass, iron, and steel, along with various alloys. They additionally deal with materials like porcelains and composites, providing to diverse commercial needs and requirements in manufacturing procedures.Just How Do Factory Provider Influence Overall Supply Chain Administration?

Shop services greatly enhance supply chain monitoring by enhancing product sourcing, decreasing preparations, and ensuring constant top quality. Their capability to give tailored options cultivates collaboration amongst stakeholders, ultimately improving total functional efficiency and responsiveness in manufacturing.What Industries Advantage Most From Factory Providers?

Industries such as auto, building, customer, and aerospace products considerably take advantage of foundry services. These industries depend on accuracy spreadings to fulfill stringent quality standards and improve their general production procedures and item efficiency.Are Shop Providers Environmentally friendly and sustainable?

Factory services can be ecologically friendly and sustainable, especially when employing sophisticated technologies and processes - Aluminum Foundry. Innovations such as recycling materials, decreasing exhausts, and maximizing power use contribute to decreasing their ecological impact in commercial applications

Just How Can Companies Choose the Right Shop Company?

Business can select the appropriate factory provider by assessing proficiency, manufacturing abilities, quality qualifications, innovation used, client reviews, and sustainability techniques while guaranteeing alignment with their certain project demands and long-term service goals.Factory services play a necessary function in boosting production performance and quality throughout numerous industrial applications. The cooperation between factories and suppliers cultivates a better understanding of production demands, leading to optimized processes and boosted item styles. Effective shop practices play a necessary role in reducing lead times within manufacturing settings. By employing advanced formulas and software program, foundries can optimize process, straightening manufacturing schedules with demand forecasts and resource accessibility. Firms that spend in top quality factory solutions not just boost their manufacturing processes but likewise distinguish themselves from rivals that might give up top quality for cost savings.

Report this wiki page